Aimix tile adhesive manufacturing plant is widely used to produce all kinds of special mortar and common mortar, such as plaster mortar, waterproof mortar, thermal insulation mortar, tile adhesive mortar, tile grout mortar, bonding mortar, screed mortar, etc. These mortars are widely used as building materials for bridges, railways, workshop, warehouse, sewerage projects, residential construction.

Aimix tile adhesive manufacturing plant has capacity of 3-30 tons per hour, they can be divided into: simple type tile adhesive production line, small type tile adhesive manufacturing plant, middle type tile adhesive manufacturing plant and fully automatic tile adhesive manufacturing plant. We also support customized. Here are details of our tile adhesive manufacturing plant:

Production circle: 20min

Produced mortar type: ordinary mortar

Power: 23.5-36.5 kw

Main parts: dry mortar paddle mixer, dry powder silo, packing spiral, etc.

Features: semi-automatic, manual feeding, no drying, no weighing, customized for dust control system.

Investment advice: low investment with fast investment return, suitable for initial/individual investment.

Production circle: 20min

Produced mortar type: ordinary mortar

Power: 23.5-36.5 kw

Main parts: twin shaft mortar mixer, storage silo, packing machine & dust collection system.

Space occupying: Usually built in two floors. Covers 20 square meters & about 6.5 m in height.

Investment advice: Appropriate to beginning investment for clients which has limits in the factory building height.

Production circle: 5 min

Produced mortar type: Ordinary mortar & special mortar

Power: 120-150 kw

Space occupying: Usually in three floors, occupied 30 square meters & 8.5 m height.

Features: Easy & convenience operation & small space occupation, low energy consumption.

Investment advice: Fast return on investment and easy upgrade to fully automatic tile adhesive production line later.

Production circle: 5 min

Produced mortar type: produce different usage dry mortar for needs, such us, Masonry mortar, plastering mortar, thermal insulation mortar, decorative mortar, etc

Mixing system: with 60~180s blending, materials are mixed evenly;

Feature: High degree of automation & Basically with bulk systems, equipped with weighing system, packaging system.

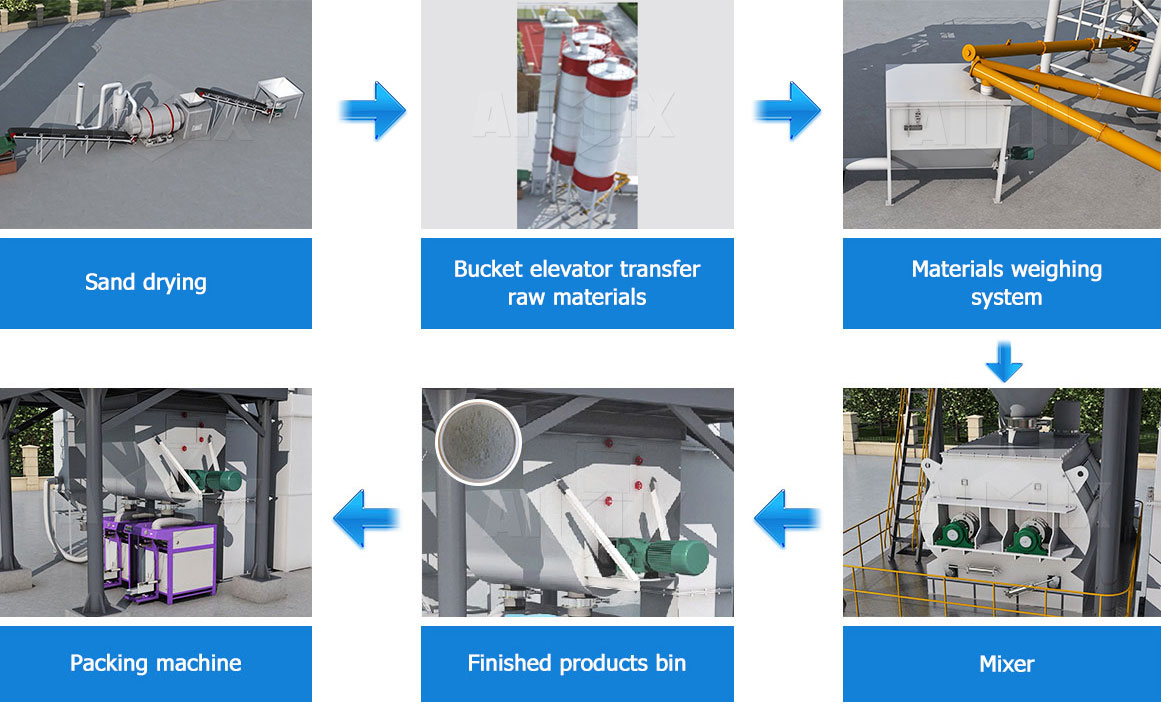

Working Procedure Of Aimix Tile Adhesive Manufacturing Plant:

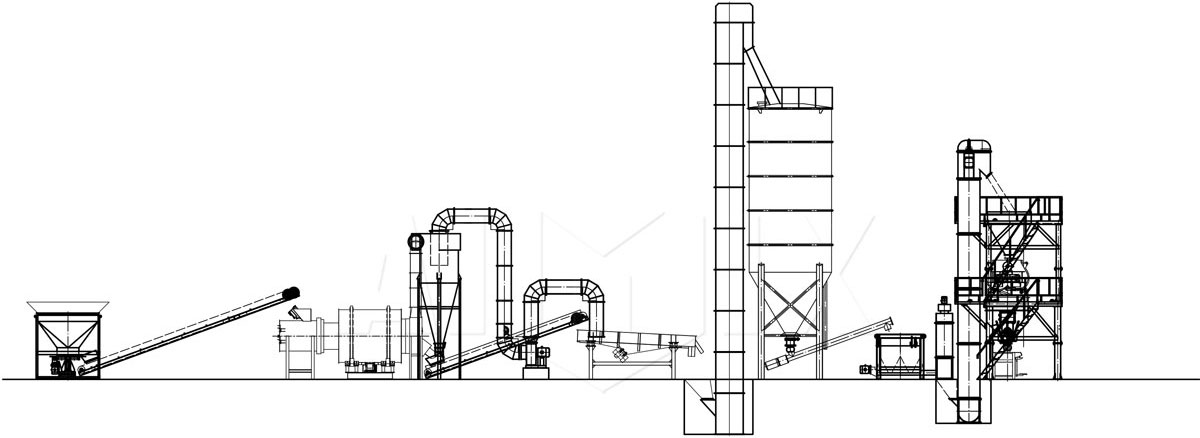

Main Parts of Aimix Tile Adhesive Manufacturing Plant: wet sand feeding system, drying system, hoist lifting system, raw material storage system, weighting system, mixing system, finished product storage bin, packing system, dust collector and control system. We also support customized service, please contact us for details.

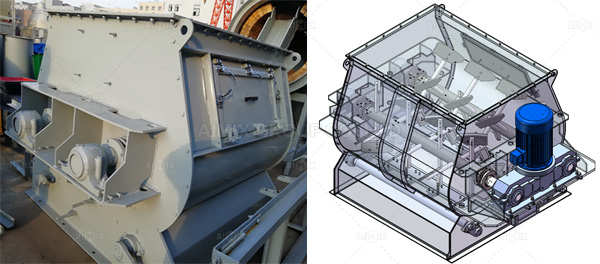

1. Shaft end seal (patent type)

2. Discharge door full open , mosaic structure, automatic adjustment of closing angle

3. Real-time automatic oiling pump, saving labor, automatic oiling and maintenance.

4. Silicone core high water-based packing (wear-resistant, impact-resistant, and good sealing)

5. Independent cylinder (meet the instantaneous air consumption)

6. Directly connected reducer

7. Stirring blade (made of chromium molybdenum titanium alloy, 20mm thick)

Aimix spiral belt type dry mortar mixer adopts the form of single shaft and three spiral belts to rapidly mix materials. With movement of spiral belt of the stirring shaft, the inner and outer spiral belts largely turn the material. The inner spiral belt moves the material to both sides, and the outer spiral belt moves the material inward from both sides, so that the material is mixed back and forth. The other part of material is driven by the spiral belt to move in the axial direction and radial direction, thus forming a convective circulation. Due to the above-mentioned mixing, the materials can be quickly and evenly mixed in a short time.

Working Process of Aimix Tile Adhesive Manufacturing Plant:

1. Generally, the raw materials are put into the drying system of tile adhesive manufacturing plant at first.

2. After drying, the raw materials are conveyed to material storage system by hoister.

3. Then, all raw materials and additives will undergo accurate weighting and even blending in the mixing system of dry mortar equipment.

4. Final process is decided by our clients: they can either pack the mortars in bags or just keep them in the finished product bin according their actual demand.

Cases Of Aimix Tile Adhesive Manufacturing Plant:

Aimix tile adhesive manufacturing plant has been exported to over 20 countries, including: Indonesia, Malaysia, Philippines, Peru, UAE, Sri Lanka, etc. Here are several cases of them. If you want to get more details, please contact us.

Aimix 30 t/h tile adhesive manufacturing plant begin put into use for dry mortar production in October, 2019. It took 10 days for tile adhesive manufacturing plant production, and 15 days shipment to Indonesia. While the equipment was shipped to Indonesia, our salesperson and resident engineer came to help our Indonesia clients for installation, commission and operation training service. Our clients high praised Aimix quality & Aimix service. Learn More

Our clients bought this 10 tph tile adhesive manufacturing plant in December 2019. Because of the infulence of Covid-19, it was deliveryed to Malaysia in June 2020. And it took 12 days to transported to Malaysia. We helped installation and running test for our Malaysia clients, and also taught them how to operate this tile adhesive manufacturing plant. Now it has been worked well for our local client and helped a lot for their tile adhesive business. Learn More

Aimix 5-6 tph tile adhesive production line was shipped to Peru in March 2021. It has been used for tile adhesive production now. Our Peru clients first inquiry in December 2020, after learning his requirement, our engineer advice him to buy this simple type tile adhesive production line. He paid for this tile adhesive production line immediately and has fast tranportation. Our Peru clients spoke highly of our good service & timely delivery, and looking for further cooperation. Learn More

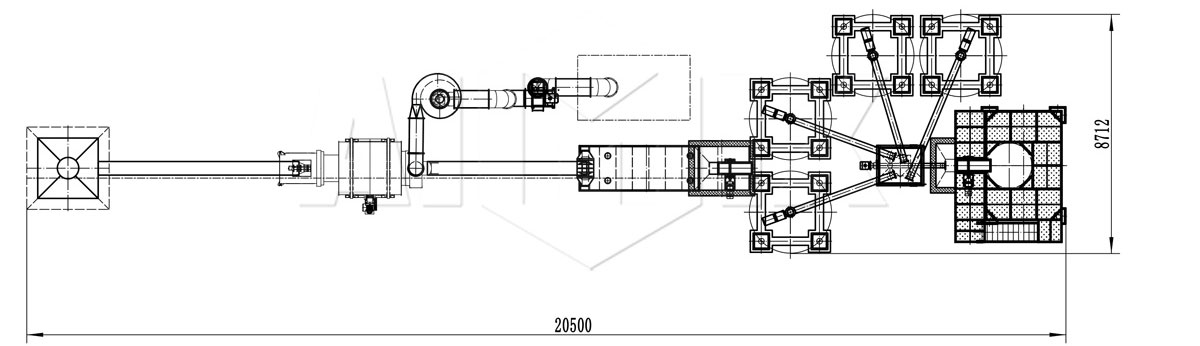

Our Indonesia clients bought Aimix 10 tph sand drying line for drying sand of his own tile adhesive production line. Our client sells tile adhesiv for local market, and has asked for Aimix sand drying line since 2019. Because of the room limits of his factory, he couldn’t bought it in 2019. Now he planed to expanding his bisness, and using Aimix sand drying line will largely save his cost of buying dry sand from local market. Learn More

Technical Parameters Of Aimix Tile Adhesive Production Line:

| Type | Productivity (t/h) | Production circle | Number of sand bins | Number of powder bins | Production mortar type | Power(kw) | Floor area |

| AF-3 | 3 | 20min | 0 | 0 | ordinary mortar | 23.5 | 20-30 ㎡ |

| AF-6 | 6 | 20min | 0 | 0 | ordinary mortar | 32.5 | 20-30 ㎡ |

| AF-9 | 9 | 20min | 0 | 0 | ordinary mortar | 36.5 | 30-40 ㎡ |

| AF-10 | 5~10 | 5min | 2x100T | 2x100T | Ordinary mortar and some special mortar |

120 | 37×10m |

| AF-20 | 15-20 | 5min | 2x100T | 2x100T | 150 | 37×10m | |

| AF-30 | 20-30 | 5min | 2x100T | 2x100T | 180 | 37×10m |

If you need other types or other capacity tile adhesive manufacturing plant, please contact us for details. We will reply you in 6 hours and provide you customized service.

Features Of Aimix Tile Adhesive Production Line:

1. The design height of tile adhesive manufacturing plant is reasonable, easy to install and maintain;

2. Investment little, easy to get profits;

3. Main systems, such as Drying System, Vibrating Screen System, Mixing System can work separately, convenient to operation;

4. Key parts of the Aimix tile adhesive manufacturing plant adopts international and domestic famous brand, extending the duration significantly;

5. Mixing system: with 60~180s blending, materials are mixed evenly;

6. Drying system: equipped with Triple-cylinder dryer to reduce the sand water content to ≤0.5%;

7. Depending on different raw materials and formulas, weighing device adopt independent system to improve the weighing accuracy greatly;

8. Equipped with dust collection system to collect dust from drying system, weighing system, mixing system and bag packing system, it efficiently protects the working and living environment;

9. Full Automatic control system, convenient for operation and management.

If you’re interested of Aimix tile adhesive manufacturing plant or want to get more details, please contact us.