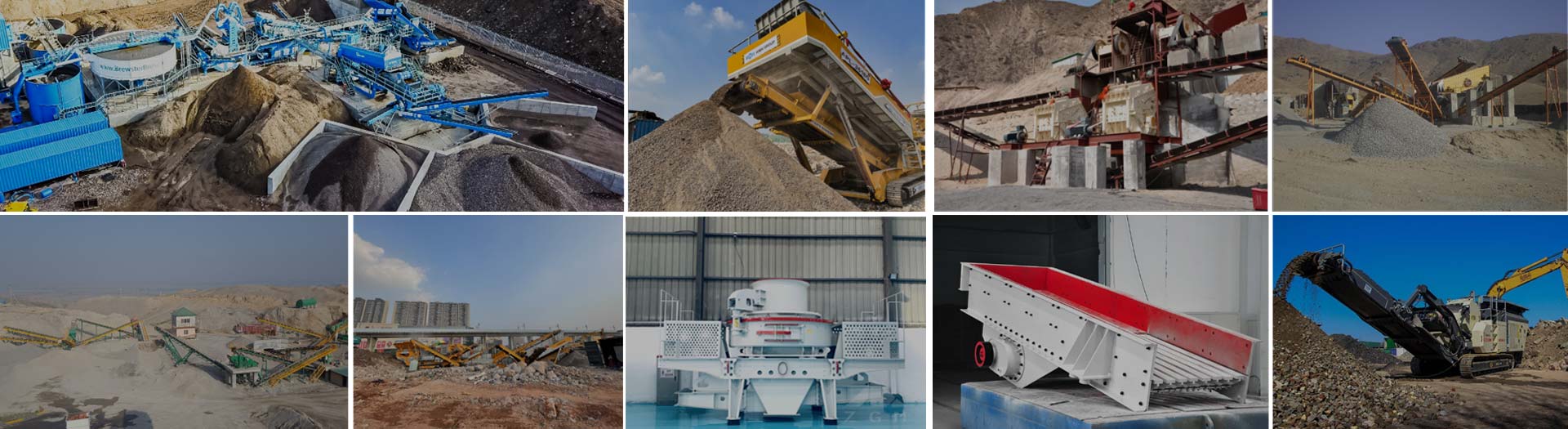

Crushing and Screening Solution

Stone Crusher Plant (Mobile & Stationary Type)

A crushing plant is also called a crushing and screening plant, Our stone crusher plants are engineered to deliver unrivaled productivity in mines, quarries and civil engineering projects. We offer advanced, proven crushing and screening equipment for any size-reduction challenge. Whether you’re producing several sized aggregates or crushing tons of hard rock ore, our solutions deliver the robustness and versatility you need.

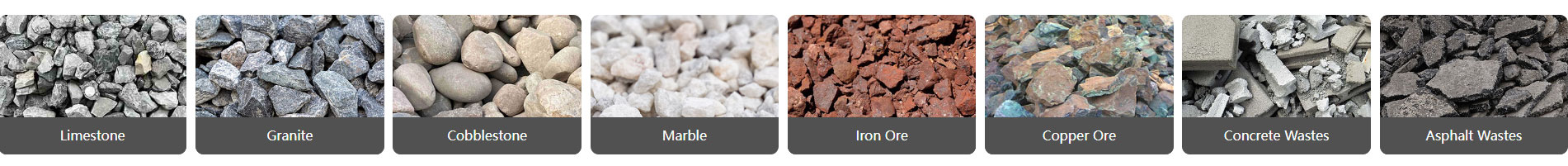

Raw Materials – Crushing Plant Can Handle

Large crushing force, a wide range of applications, laminated crushing, energy saving and consumption reduction. Raw Material: river stone, rock stone, pebbles, Limestone, granite, marble, basalt, iron ore, shale, coal, construction waste

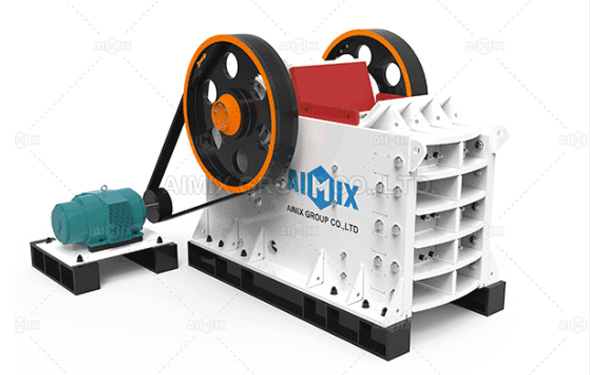

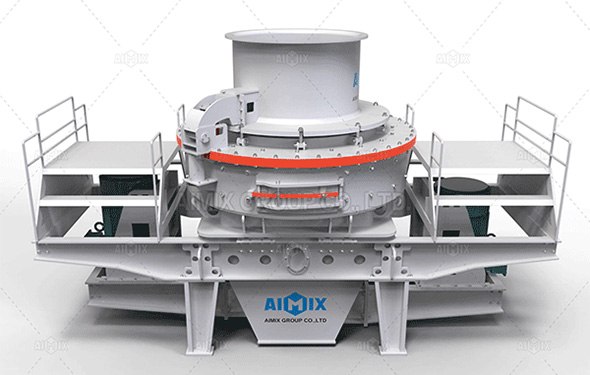

Different Types of Crushers used in Crushing Plant

To achieve different crushing purposes of clients, we have different combinations of crushers, there are more and more types of crushers, such as jaw crushers, cone crushers, impact crushers, VSI crushers, etc. The current four types of stone crushers are detailed as follows:

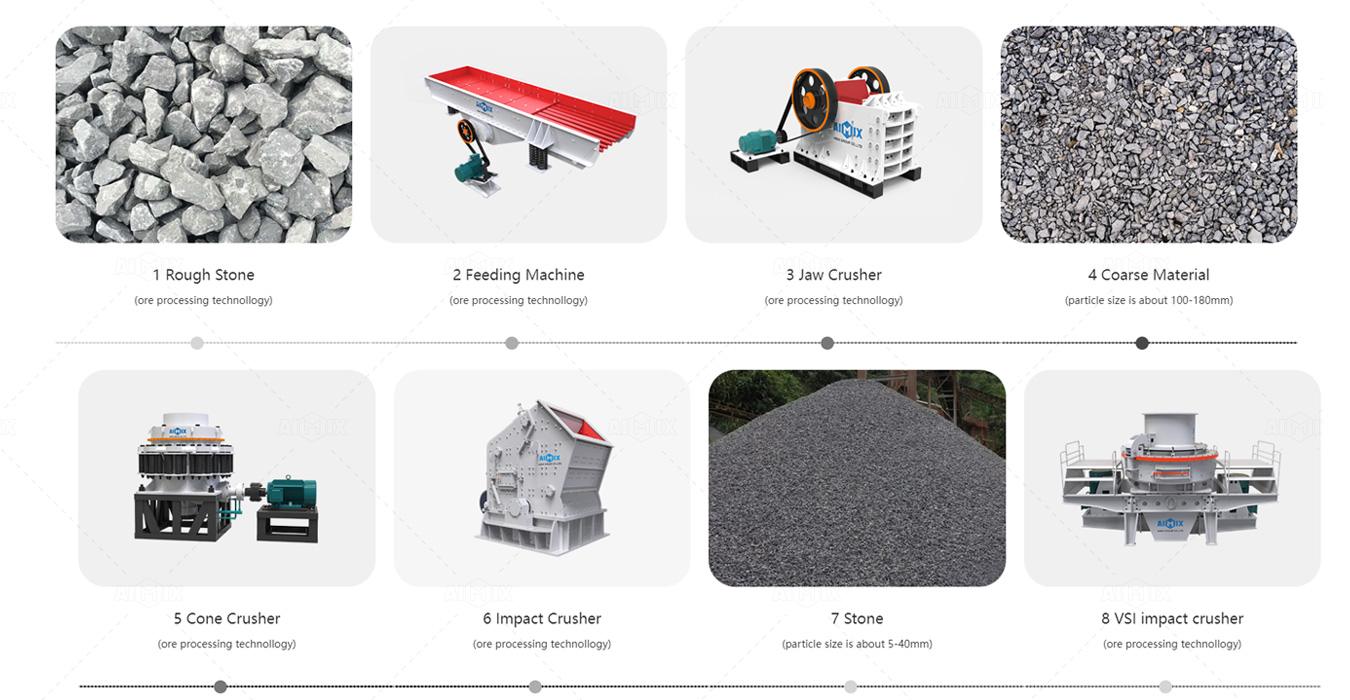

Production Process of an Crushering Plant:

These crusher plants provide the consistency that is crucial to your crusher quality. All plant processes and components are carefully developed to ensure that feeding, crushing, screening, secondary crushing, sand making, and discharging blend together.

Aimix Cases Of Crusher Plants in Different Countries

Aimix crushing plants have become increasingly popular worldwide due to their efficiency, reliability, and versatility. These plants have been exported to various countries, for example: the Philippines, Malaysia, Indonesia, Australia, Saudi Arabia, Paraguay, Peru, Chile, Tanzania, Democratic Republic of the Congo, Fiji, Papua New Guinea, Guyana, Jamaica, etc;