Stabilized soil mixing plant mix stable gravel soil, lime stabilized soil and etc. It can use quicklime, hydrated lime(moisture content10~15%), soil, sand, fly ash, cement and other raw materials, to produce lime soil stabilized base material and cement stabilized gravel, can be pressed concrete base material.

Stabilized soil mixing plant is suitable for high grade highway, railway, airport, municipal construction, the production of different specifications to stabilized soil base course material.

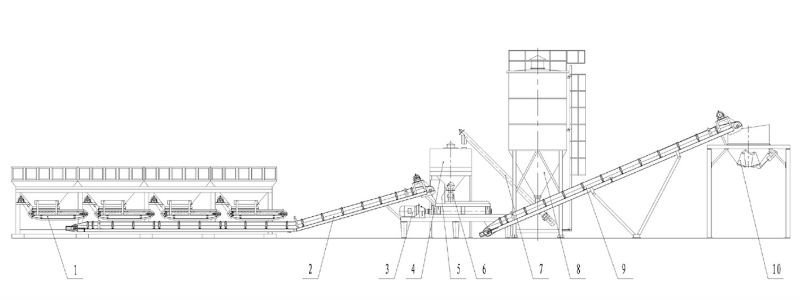

This MWCB series stabilized soil mixing plant is a special mixing plant for achieving the continuous even mixing of the variety of stabilized road base materials which has the high matching accuracy (in accordance with the requirements of raw materials), so it is widely used in the construction fields of road, airport, dock and other stabilized road base material construction project.

YMWCB series Mobile type stabilized soil mixing station equipment is Aimix ‘s continuous development and upgraded model of stable soil mixing equipment, which is very suitable for short term or medium term projects to produce stabilized soil for road base, airport, stadium and etc; It has the advantages of excellent equipment performance, advanced technology, reasonable structure, reliable work, convenient use, easy repair, high productivity, accuracy ratio, mix evenly. It is the ideal base material mixing device to construction unit.

Technical Parameters Of Aimix Stabilized Silo Mixing Plant :

| Stationary Type Stabilized Soil Mixing Plant | Mobile Type Stabilized Soil Mixing Plant | Working Process Video |

|---|

| Parameter model | WCB300 | WCB400 | WCB500 | WCB600 | WCB700 | WCB800 |

| Maximum production capacity(t/h) | 300 | 400 | 500 | 600 | 700 | 800 |

| Mixing form | Double horizontal axis continuous forced type | |||||

| Powder metering accuracy(%) | ±1 | |||||

| Aggregate measurement accuracy(%) | ±2 | |||||

| Powder measurement method | Helix electronic scale | |||||

| Aggregate measurement method | Computer belt scale | |||||

| Volume of aggregate hopper(m³) | 12 m³*4 | 12 m³*4 | 12 m³*4 | 12 m³*5 | 12 m³*5 | 12 m³*5 |

| Powder bin capacity(t) | 100 | 100 | 100 | 100*2 | 100*2 | 100*2 |

| Tank volume(m³) | 8 | 8 | 8 | 8 | 8 | 8 |

| Volume of finished product warehouse(m³) | 10 | 10 | 10 | 10 | 10 | 10 |

| Whole machine power(kw) | 90 | 110 | 130 | 150 | 165 | 190 |

| Parameter | YWCB300 | YWCB300 | YWCB400 | YWCB500 | |

| Maximum capacity(t/h) | Gravel | 200 | 300 | 400 | 500 |

| Lime soil | 150 | 200 | 300 | 400 | |

| Mixing method | Double horizontal shaft forced continuous mixing | ||||

| Powder measurement precision (%) | ±1 | ±1 | ±1 | ±1 | |

| Measurement precision of aggregate (%) | ±1 | ±1 | ±1 | ±1 | |

| Aggregate metering modes | Screw electronic scale | ||||

| Powder measurement method | Computer control belt scale | ||||

| Aggregate hopper volume(m3/a) | 6 | 8 | 8 | 10 | |

| Powder bunker capacity(t/a) | 100 | 100 | 100 | 100 | |

| Water tank volume(m3) | 5 | 8 | 8 | 10 | |

| Finished product warehouse volume(m3) | 8 | 10 | 10 | 10 | |

| Total power(Kw) | 70 | 90 | 110 | 130 | |

If you need other types and capacity stabilized soil mixing plant, our professional engineers can design according to your demand and provide free installation, maintenance and other services. Please click Contact us.

The Main Features Of Aimix Stabilized Silo Mixing Plant :

1. Adopting double horizontal shaft continuous mixer.

2. Equipped with an industrial computer for automatic control and it can be operated manually or automatically.

3. The modular structure facilities the installation of transportation.

4. The batching plant is equipped with an electronic belt scale and electronic screw scale, with better batching accuracy.

5. The water supply system adopts a turbine flow transducer.

6. It can realize containerized transport.