AIMIX GROUP provide various small or mini capacity mobile crushing vehicles, which is cost effective and can meet aggregate daily needs for mini concrete batching plant, dry mortar mix plant, concrete mixer pump, self loading concrete mixer, etc project. Numerous Aimix clients order Aimix mobile crushing machine for their construction project and have good user feedback. Aimix mini mobile stone crushing machines mostly are tire type, which also can be tracked type by client customized requirement.

AIMIX GROUP provide various small or mini capacity mobile crushing vehicles, which is cost effective and can meet aggregate daily needs for mini concrete batching plant, dry mortar mix plant, concrete mixer pump, self loading concrete mixer, etc project. Numerous Aimix clients order Aimix mobile crushing machine for their construction project and have good user feedback. Aimix mini mobile stone crushing machines mostly are tire type, which also can be tracked type by client customized requirement.

Our mini mobile crushing machine mobile crushing machine mainly includes three types:

3-5t/h Fine Jaw Crusher

6-15t/h Hammer Crusher

30-50t/h Box Type Crusher Vehicle

Mobile Type Fine Jaw Crusher:

Features:

1. Small size for convenient handling and dragging.

2. Diesel power generation or pure electric is optional.

3. It can be delivered manually or fed by belt.

4. Simple operating, high productivity and low investment cost.

5. It is suitable for primary and secondary crushing of all kinds of minerals and rocks with compressive strength less than 320 mpa.

Technical Parameters of Mobile Fine Jaw Crusher:

| Model | PEX-150×750 | PEX-250×750 | PEX-250×100 |

| Feeding Opening Size (mm) | 150×750 | 150×750 | 250×1000 |

| Max Feeding Size(mm) | 120 | 210 | 210 |

| Adjustable Discharging Range(mm) | 18-48 | 25-60 | 25-60 |

| Capacity(t/h) | 8-25 | 13-35 | 16-52 |

| Eccentric Shaft Speed (r/min) | 310 | 330 | 330 |

| Motor Power (KW) | 15 | 30 | 30 |

| Weight(t) | 2.9 | 4.8 | 6.8 |

| Dimension (L*W*H) (mm) | 1215×1530×1060 | 1380×1750×1540 | 1560×1950×1390 |

Structure of Mobile Fine Jaw Crusher:

♦High-quality frame: High-quality cast iron with sufficient strength and rigidity

♦Moving jaw rod: Cast iron shaft plate improves safety factor for protecting crusher components

♦Flywheel: Balance the inertia and promote the normal operation of the machine

♦Body paint: The body paint uses baking paint, which is simple and beautiful.

Mobile Hammer Crusher:

Mobile Hammer Crusher

Output Capacity: 6-15 t / h

The mobile crushing truck configured according to the small hammer breaking model has a simple structure, can be dragged and moved, is driven by a diesel engine, and can be delivered manually or fed by a belt.

The crushed product is gravel aggregate which can be controlled at 20-50mm.

There are currently four models with optional configurations.

Technical Parameters of Aimix Mobile Hammer Crusher:

| Type | 60 | 80 | 100 | 1200 |

| Motor Power(kw) | 37 kw | 55 kw | 75 kw | 110 kw |

| Width of conveyor(mm) | 600 mm | 800 mm | 1000 mm | 1200 mm |

| Width of Feed opening(mm) | 600×550 mm | 800×580 mm | 1000×650 mm | 1200×800 mm |

| Dimension(L*W*H) | 10×2.4×2.6 m | 10×2.6×2.8 m | 11×2.8×3 m | 12×3×3.2 m |

| Weight(t) | 30 t | 50 t | 80 t | 120 t |

| Capacity(t/h) | 6 t/h | 7 t/h | 8 t/h | 13 t/h |

Details of Aimix Mobile Hammer Crusher:

♦ High manganese sieve bottom

Thicker high manganese sieve bottom, more wear-resistant, longer life.

♦ Hammer breaking silo

The silo is equipped with single-cylinder, which effectively prevents material tuck and increase the space.

♦ Forging Crusher

The crushing hammer is forged at high temperature, strong, wear-resistant, and wayward.

♦ Conveying Part

Thicker tracks, more stable and faster delivery.

Box Type Crusher Vehicle:

Box Type Crusher Vehicle:

Output Capacity: 30-50 t/h

The mobile crushing truck configured according to the box hammer crusher

It has a simple structure which can be dragged and moved conveniently.

It is equipped with a hybrid electric drive which can be loaded by a belt or a forklift.

The crushed finished product is gravel aggregate that can be controlled at 40-50mm.

Technical Parameters of Aimix Box Type Crusher Vehicle:

| 1016 Mobile Crushing Plant | APY50 & APY70 Mobile Crushers |

|---|

| Model | 1016 Mobile Crushing Plant |

| Production Capacity | 5 cm sieve about 50 t/h |

| Hopper Size | 5×2.3m |

| Max. Feeding Size | ≤30 cm |

| Vibration Feeder | 11 kw |

| Output Conveying Motor | 7.5 kw |

| Main Power | 160 kw |

| Conveyor Belt Width | 1.2 m |

| Output Conveying Height | 3.1 m |

| Overall Weight | 20 ton |

| Overall Size | 12×3×3.1 m |

| Name | APY50 Mobile Crusher | APY70 Mobile Crusher |

| Engine Power | Diesel 6110 75 kw | Diesel 6126 125 kw |

| Input Size(mm) | 800×80 mm | 1000×1000 mm |

| Conveying Belt Size(mm) | 8200×800 mm | 8200×1000 mm |

| Overall Dimension(mm) | 12000×2600×3500 mm | 12000×2800×3500 mm |

| Capacity(t/h) | 30-50 t/h | 50-70 t/h |

| Storage Port Size(mm) | 3620×150 mm | 3780×1875 mm |

| Overall Weight(t) | 13 t | 15 t |

Details of Aimix Box Type Crusher Vehicle:

Simple and convenient operation

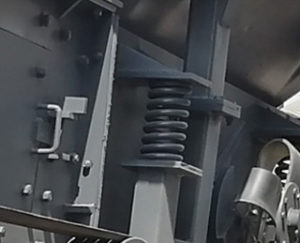

♦ Bold spring

Bold spring, strong vibration force, durable

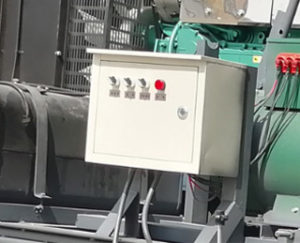

♦ Powerful motor

Brand high power motor, powerful and durable

Thick solid tires, more robust and wear-resistant

♦ Vibration feeder

Hopper feeders are thickened middle plate, eccentric vibration.

♦ High wear-resistant hammer head

Special high wear-resistant hammer head, which can extend the service life by 3-4 times.