Aimix offers a wide range of medium mobile crushing, screening solutions for quarrying, recycling, contracting and mining applications. Our mobile crushing plant meet high demands for mobility both on site and on the road. Available on crawlers, they are compact, very stable and of low weight. Since the different units are compatible with each other, it is easy to combine one or more units, depending on the fractions required.

1.Equipped with a large jaw crusher master device, large crushing ratio

2.Versatile mobile jaw crusher with high capacity

3. Compact Chassis Frame, shorten the length of transportation

4. Pre-screening function, powerful processing capacity

5. Adaptive host device switch, meet clients required needs

6. Flexible parking function, quickly access to the operating mode

1. Crawler type mobile crushing and screening plant is low consumption, low noise, reliable performace.

2. High intensity, easy to be transported on the different landform like mountain and marsh.

3. It adopts the motor of high-torque and strong driving force.

4. Crawing system adopts full-power variable open hydraulic system which is of excellent performance, high reliability.

5. Its structure is compact. The screen is installed in 20 degree angle, so the screening is highly efficient.

Technical Parameters of Aimix Mobile Crushing Plant:

| Series | Standard Model | Feeding Equipment | Crushing Equipment | Transportation dimension | Weight (t) |

| Model | Model | Disassembly L*W*H(mm) | |||

| Primary Crushing Plant | KE600-1 | TSW0936 | PE600*900 | 12150*2600*3950 | 43 |

| KE750-1 | TSW1139 | PE750*1060 | 13000*2850*4400 | 61 | |

| KE760-1 | TSW1139 | PEW760 | 13000*2800*4200 | 55 | |

| KE860-1 | TSW1345 | PEW860 | 14600*3000*4500 | 64 | |

| KE1100-1 | TSW1548 | PEW1100 | 14050*2900*4000 | 96 | |

| KF1214Ⅱ-1 | TSW0936 | PFW1214Ⅱ | 12150*2600*3980 | 48 | |

| KF1214Ⅱ-1 | TSW1139 | PFW1214Ⅱ | 13000*2800*4200 | 53 | |

| KF1315Ⅱ-1 | TSW1345 | PFW1315Ⅱ | 14600*3100*4500 | 61 | |

| KF1415Ⅱ-1 | TSW1548 | PFW1415Ⅱ | 14050*3000*4000 | 74 | |

| Any change of technical data shall not be advised additionally. | |||||

| Secondary crushing and screening plant |

KC75-2 | 3YZS1848 | CSB75 | 12600*3000*4500 | 41 |

| KC160-2 | 3YZS1860 | CSB160 | 13800*3000*4500 | 59 | |

| KT100-2 | 3YZS1848 | HST100H | 12600*3000*4500 | 32 | |

| KT160-2 | 3YZS1860 | HST160H | 13800*3000*4500 | 41 | |

| KT250-2 | 3YZS1860 | HST250H | 13800*3000*4500 | 49 | |

| KT250-2 | 3YZS2160 | HST250H | 13800*3000*4500 | 53 | |

| KH300-2 | 3YZS1860 | HPT300 | 13800*3000*4500 | 50 | |

| KH300-2 | 3YZS2160 | HPT300 | 13800*3000*4500 | 54 | |

| KH300-2 | 4YZS2160 | HPT300 | 13800*3150*4500 | 56 | |

| KF1214-2 | 3YZS1860 | PF1214 | 13800*3000*4500 | 53 | |

| KF1214-2 | 3YZS1860 | PFW1214Ⅲ | 13800*3000*4500 | 50 | |

| KF1315-2 | 3YZS2160 | PF1315 | 13800*3150*4500 | 62 | |

| KF1315-2 | 3YZS2160 | PFW1315Ⅲ | 13800*3150*4500 | 60 | |

| KF1315-2 | 4YZS2160 | PFW1315Ⅲ | 13800*3150*4500 | 62 | |

| KF1318-2 | 3YZS2160 | PFW1318Ⅲ | 13800*3150*4500 | 66 | |

| KS1848-1 | 3YZS1848 | 12590*3000*4500 | 26 | ||

| KS1860-1 | 3YZS1860 | 13800*3000*4500 | 27 | ||

| KS2016-1 | 3YZS2160 | 13800*3000*4200 | 31 | ||

| Any change of technical data shall not be advised additionally. | |||||

If you are interested in Aimix Mobile crushing plant, please Contact us directly for a free quotation, we will reply to you sooner.

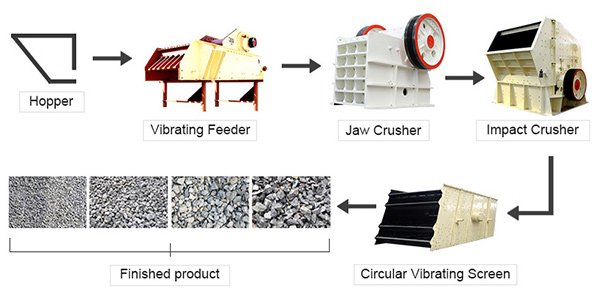

Working Process of Aimix Mobile Crushing Plant:

The big rocks are smoothly fed into the jaw crusher by the feeder, and the crushed will be delivered into impact crusher for secondary crushing by belt conveyor, then screened by vibrating screen. For those unqualified materials, they will be delivered into impact crusher again for tertiary crushing. The sizes of finished product are 0-5mm, 5-10mm, 10-20mm, 20-30mm.