The hydraulic system ensures the concrete pumping accuracy and pumping efficiency.

The engine adopts Weichai engine or Cummins engine, which has stable operation and low failure rate.

AIMIX provides three types of concrete mixer pump: ABJZ series concrete mixer pump, ABJW series concrete pan mixer pump and ABY concrete boom mixer pump. Our concrete mixer pumps combines concrete mixing and concrete pumping for our roads, buildings, railways, tunnels construction. .

Concrete Mixer Pump:

With their own diesel power, ABJW30C and ABJW40C avoids the inconvenience of electricity and makes construction more convenient; the combination of the mixer and the concrete pump makes the whole machine easy to transport and transfer on site. The mixing and pumping functions are integrated, which is convenient for transfer and move.

Models: ABJZ30C, ABJZ40C

Max. concrete output(L./H): 30-40 m³

Max. pumping pressure(H./L.): 8-10 Mpa

Vertical Convey Distance: 120m-150 m

Horizontal Convey Distance: 400m-600 m

Max.aggregate diameter: Slick/scree: 20-40 mm

Diesel engine model: Weichai/Cummins

Get A Quote

Models: ABJZ30D, ABJZ40D

Max. concrete output(L./H): 30-40 m³/h

Max. pumping pressure(H./L.): 8-10 Mpa

Distribution valve type: S Valve

Electrical engineering power: 37/45 kw

Vertical Convey Distance: 120m-150m

Horizontal Convey Distance: 300m-500m

Max. aggregate diameter:Slick/scree: 20-40mm

Get A Quote

New Coming! Concrete Mixer Pump – With a Vertical Shaft Planetary Mixer

AIMIX ABJW Concrete Pan Mixer Pump is our company’s latest mixer pump, equipped with a Vertical Shaft Planetary Mixer. Compared with previous concrete mixer pump, this product adopts a dual hydraulic drive, and uses two mixing shafts to mix the concrete. Compared with traditional mixers, there is one more mixing shaft for mixing, and the mixing speed of concrete is increased by 2-3 times, with a mixing efficiency of 40m3 per hour.

ABJW Concrete Mixer Pump

Power: Diesel

Diesel Diesel engine model: Weichai/Cummins

Concrete Mixer: Vertical Shaft Planetary Mixer

Capacity(m3/h): 30m3/h-40m3/h

Concrete Puming Distance: 280m(Vertical)/1200m(Horizontal)

Suitable for road and building construction projects, it can pump horizontally up to 1200 meters and vertically up to 280 meters (approximately 35-50 story buildings).

Get A Quote

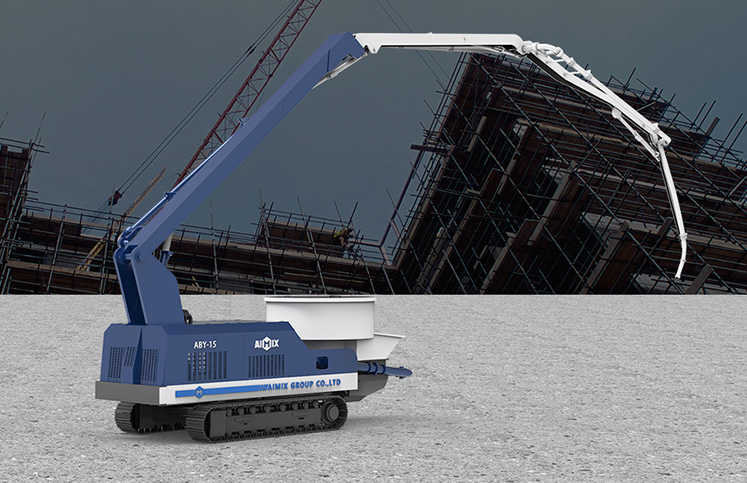

Boom Mixer Pumps

A concrete boom mixer pump is the latest product developed by our AIMIX GROUP to provide our customers with a more compact and convenient concrete mixing + pumping solution. It merges the functions of a concrete mixer and a concrete boom pump, making it an ideal addition to a fleet of concrete pumps.

Max. concrete output(L./H): 89 m³/h

Boom sections: 4

Mixer: New Pan Mixer

Pump Convey Distance: 20m, 26m, 30m, 33m

Application: Mainly used in rural civil construction and drain construction, etc.

Advantages: New rotary mixer, double pumping mixing, more efficient and more uniform.

Get A Quote

Max. concrete output(L./H): 50 m³/h

Boom sections: 4

Mixer: New Pan Mixer

Pump Convey Distance: 8m, 15m, 18m, 20m, 25m

Application: Mainly used in mountainous areas, farmland drainage, and places that concrete transport trucks cannot reach.

Advantages: Crawler chasis; Remote control available.

Get A Quote

Max. concrete output(L./H): 120 m³/h

Boom sections: 5

Mixer: New Pan Mixer

Pump Convey Distance: 26m, 30m, 33m, 38m

Application: Ideal for farmland drainage, rural civil construction, etc. It can reach any place, especially in narrow working spaces.

Advantages: CLight weight, short wheelbase, small body, compliant with regulations, large operating space, high construction efficiency.

Get A Quote

Application Fields

AIMIX concrete mixer pump is ideal for commercial housing construction, road and bridge construction projects in big cities. It is also suitable for floor heating, spraying concrete project and spraying refractory material, and is more suitable for urban and rural residential buildings of 5-10 floors and new rural construction.

Rural housing construction

Urban building construction

Bridge and canal construction

Road construction: urban and rural road, highway tunnels, etc.

Concrete Mixer Pump For Concrete Mixing And Pumping Solution:

1. Wheel loader feeds aggregate feeding to the batching machine,

2. The batching machine is used for aggregate storage and automatic weighing to ensure the concrete quality;

3. Feed the aggregate to our concrete mixer pump to mix and pump.

Global Cases of Aimix Concrete Mixer Pumps:

As a construction equipment manufacturer with more than 40 years of experience, our equipment has been sold to more than 100 countries and regions around the world, for example: the Philippines, Malaysia, Indonesia, Saudi Arabia, Oman, UAE, Jamaica, Nigeria, Guyana, Ethiopia, Dominica, Tanzania, Uganda, etc. We provide concrete production and transportation solutions to many customers around the world to help customers’ construction projects.

Client’s project: Building Construction Project.

ABJZ40C diesel concrete mixer pump has been shipped to the Philippines and working normally at the construction site, The customer bought the concrete mixer pump equipment for his own factory house construction project. he needs to build several houses to expand the factory.

Client’s project: Resort construction project.

Brief introduction: Our client is an real estate developer in Oman, and these machines will be used for his new resort construction project. These machines were transported to Oman by sea transportation. Our concrete mixer pump is used for concrete mixing and pumping and our block machine is responsible for the production of concrete bricks. Our clients spoke highly of this combination because of its labor-saving & cost-effective. Learn More

Client’s project: Country house construction project.

Brief introduction: Our client used this ABJZ40C mixer pump to build rural houses, significantly improving efficiency and quality. It provided consistent concrete mixing, saving time and labor, especially in remote areas. This reliable tool helped complete the project on schedule, delivering sturdy homes for the community.Learn More

More Cases of Aimix Concrete Pumps

ABT30C Concrete Tralier Pump In Indonesia

ABT40C Concrete Tralier Pump In Myanmar

ABT40C Concrete Tralier Pump In Myanmar

ABJZ40C Concrete Mixer Pump In Jamaica

ABJZ30C Concrete Mixer Pump In Indonesia

ABJ40C Concrete Mixer Pump In Fiji

ABJZ40C Concrete Mixer Pump In Indonesia

ABT40C Concrete Tralier Pump In The Philippines

ABT40C Concrete Tralier Pump In East Timor

ABT40C Concrete Tralier Pump In Fiji

Advantages of Aimix Concrete Mixer Pump:

♦ High Quality: ISO/SGS Certificated concrete pump mixer with long working period and low maintenance cost.

♦ Good Service: We supply some free spare parts of machines and tools.

♦ Quality Control: There will be strict inspection and testing for every order before shipping out by our experienced QC.

♦ Customize Support: You can have your own logo on the machine. We also provide OEM service.

♦ After-Sale Service: Equipment installation, commissioning, machine operator & administrator training, free technical support, etc.

After Sales Service:

2. It is very important that the after-sales service team can be timely contacted and solve your problem rapidly if you encounter any operational problems in the later period. So you should consider if your manufacturer has an after-sales service team as well.

3. Localized service teams and overseas warehouses are also necessary. After the equipment has been used for a period of time, some wearing parts will need to be replaced. If the manufacturer can arrange overseas warehouses locally and arrange for professionals to replace wearing parts and maintain equipment in time for you, it will greatly facilitate your later use and prolong the service life of the equipment.