Operates around the clock, stable performance, with a failure rate

lower than 1%.

The pumping pressure is sufficient to meet the usage requirements

of high-rise building construction projects.

Concrete Mixer Pump Types

Concrete Mixer Pump combines concrete mixing and pumping function. It is used for low- and medium-rise construction projects, where commercial concrete is not convenient to deliver, and can be matched with a batching machine to become a small mixing and pumping station.

Diesel Concrete Mixer Pump

Power: Diesel

Capacity(m3/h): 30m3/h-40m3/h

Concrete Puming Distance: 280m(Vertical)/1200m(Horizontal)

Concrete production and pumping are integrated. Suitable for producing concrete on small construction projects and pumping it to specified locations or heights.

Remote Areas: In remote areas without a stable power supply, diesel trailer pumps are ideal as they do not rely on external power sources.

Get A Quote

Electric Concrete Mixer Pump

Power: Electric

Concrete Output: 30m3/h; 40m3/h

Concrete Puming Distance: 120m(Vertical)/600m(Horizontal)

Applied in urban environments where power supply is stable and easily accessible, electric trailer pumps are preferred due to their low noise and zero emissions.

Get A Quote

New Coming! Concrete Mixer Pump – With a Vertical Shaft Planetary Mixer

AIMIX ABJW Concrete Pan Mixer Pump is our company’s latest mixer pump, equipped with a Vertical Shaft Planetary Mixer. Compared with previous concrete mixer pump, this product adopts a dual hydraulic drive, and uses two mixing shafts to mix the concrete. Compared with traditional mixers, there is one more mixing shaft for mixing, and the mixing speed of concrete is increased by 2-3 times, with a mixing efficiency of 30m3-60m3 per hour.

ABJW Concrete Mixer Pump

Power: Diesel

Diesel Diesel engine model: Weichai/Cummins

Concrete Mixer: Vertical Shaft Planetary Mixer

Capacity(m3/h): 30m3/h-60m3/h

Concrete Puming Distance: 280m(Vertical)/1200m(Horizontal)

Suitable for road and building construction projects, it can pump horizontally up to 1200 meters and vertically up to 280 meters (approximately 35-50 story buildings).

Get A Quote

Boom Mixer Pumps

A boom mixer pump merges the functions of a concrete mixer and a concrete pump, making it an ideal addition to a fleet of concrete pumps. Equipped with either a wheel or crawler chassis, it is always prepared for trips to smaller construction sites, canal projects, and more. With boom mixer pump, it is no need to install the pump pipe. Tracks/tires with easy movement help you cast concrete to anywhere you want.

ABY Wheel-type Boom Mixer Pump

Max Concrete Output: 89m³/h

Hot Model: ABY20, ABY26

Boom sections: 4

Mixer: New Pan Mixer

Application: Mainly used in rural civil construction and drain construction, etc.

Advantages: New rotary mixer, double pumping mixing, more efficient and more uniform.

Get A Quote

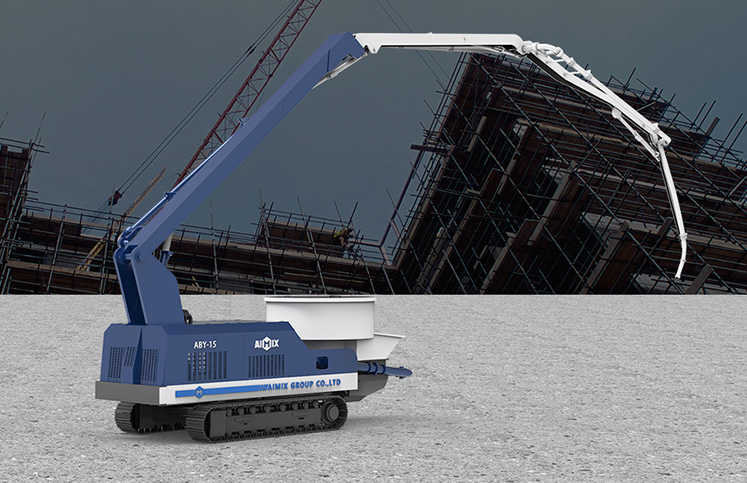

ABY Crawler-type Boom Mixer Pump

Max Concrete Output: 50m³/h

Hot Model: ABY18

Boom sections: 4

Mixer: New Pan Mixer

Application: Mainly used in mountainous areas, farmland drainage, and places that concrete transport trucks cannot reach.

Advantages: Crawler chasis; Remote control available.

Get A Quote

ABY Truck-type Boom Mixer Pump

Max Concrete Output: 120m³/h

Hot Model: ABY33

Boom sections: 5

Mixer: New Pan Mixer

Application: Ideal for farmland drainage, rural civil construction, etc. It can reach any place, especially in narrow working spaces.

Advantages: Light weight, short wheelbase, small body, compliant with regulations, large operating space, high construction efficiency.

Get A Quote

Application Fields

AIMIX concrete pump is ideal for commercial housing construction, road and bridge construction projects in big cities. It is also suitable for floor heating, spraying concrete project and spraying refractory material, and is more suitable for urban and rural residential buildings of 5-10 floors and new rural construction.

Rural housing construction

Urban building construction

Bridge and canal construction

Road construction: urban and rural road, highway tunnels, etc.

Parameters

| Items | Units | ABT40C | ABT60C | ABT80C | |

|---|---|---|---|---|---|

| whole performance of machine | Max. theo. concrete output(L./H) | M3/h | 40/26 | 67/45 | 84/45 |

| Max.concrete pumping pressure(H./L.) | MPa | 10/8 | 13/7 | 16/7 | |

| Distribution valve type | S Valve | S Valve | S Valve | ||

| Concrete cylinder diameter x stroke | mm | Φ180X1300 | Φ200X1650 | Φ200X1800 | |

| Hopper capacity x feeding height | L/mm | 400/1250 | 800/1400 | 800/1400 | |

| Outlet diameter | mm | Φ150 | Φ180 | Φ180 | |

| Power system | Diesel engineering power | KW | 82 | 129 | 176 |

| Rotate speed | r/min | 2200 | 2200 | 2200 | |

| Hydraulic system | Circuit type | Open circuit | Open circuit | Open circuit | |

| Pumping system pressure | MPa | 32 | 32 | 32 | |

| Mixing system pressure | MPa | 10 | 10 | 10 | |

| Capacity of oil tank | L | 370 | 560 | 560 | |

| Other parameters | Max. Theoretical Vertical/Horizontal Conveying Distance | m | 120/500 | 180/1000 | 260/1200 |

| Max. aggregate diameter | mm | Slick/scree:40 | Slick/scree:40 | Slick/scree:40 | |

| Inside diameter of delivering pipe | mm | Φ125 | Φ125 | Φ125 | |

| Dimensions: length x width x height | mm | 5000x1850x1700 | 5800x2000x1750 | 6300x2100x2350 | |

| Total weight | kg | 4500 | 6500 | 6900 | |

| Items | Units | ABT40D | ABT60D | ABT80D | |

|---|---|---|---|---|---|

| whole performance of machine | Max. theo. concrete output(L./H) | M3/h | 40/26 | 60/36 | 84/46 |

| Max.concrete pumping pressure(H./L.) | MPa | 10/8 | 13/7 | 16/7 | |

| Distribution valve type | S Valve | S Valve | S Valve | ||

| Concrete cylinder diameter x stroke | mm | Φ180X1300 | Φ200X1650 | Φ200X1800 | |

| Hopper capacity x feeding height | L/mm | 400/1250 | 800/1400 | 800/1400 | |

| Outlet diameter | mm | Φ150 | Φ180 | Φ180 | |

| Power system | Electrical engineering power | KW | 45 | 90 | 110 |

| Rotate speed | rpm | 1480 | 1480 | 1480 | |

| Hydraulic system | Circuit type | Open circuit | Open circuit | Open circuit | |

| Pumping system pressure | MPa | 28 | 28 | 32 | |

| Mixing system pressure | MPa | 10 | 10 | 10 | |

| Capacity of oil tank | L | 370 | 560 | 560 | |

| Other parameters | Max. Theoretical Vertical/Horizontal Conveying Distance | m | 120/500 | 160/800 | 200/1000 |

| Max. aggregate diameter | mm | Slick/scree:40 | Slick/scree:40 | Slick/scree:40 | |

| Inside diameter of delivering pipe | mm | Φ125 | Φ125 | Φ125 | |

| Dimensions: length x width x height | mm | 4500x1750x1600 | 5500x2000x1750 | 5800x2100x2350 | |

| Total weight | kg | 3200 | 6000 | 6300 | |

| Items | Units | ABJZ30C | ABJZ40C | |

|---|---|---|---|---|

| Whole performance of machine | Max. theo. concrete output | m3/h | 30 | 40 |

| Max.concrete pumping pressure | MPa | 6 | 10 | |

| Distribution valve type | S Valve | S Valve | ||

| Concrete cylinder diameter×stroke | mm | Ф200×500 | Ф180×1000 | |

| Hopper capacity | L | 400 | 400 | |

| Outlet diameter | mm | Ф150 | Ф150 | |

| Power system | Diesel engine model | Yuchai | Weichai | |

| Rotate speed | r/min | 2200 | 2200 | |

| Hydraulic system | Circuit type | Open circuit | Open circuit | |

| Pumping system pressure | MPa | 28 | 31.5 | |

| Mixing system pressure | MPa | 6-8 | 6-8 | |

| Capacity of oil tank | L | 350 | 350 | |

| Other parameters | Max. Theoretical Vertical/Horizontal Conveying Distance | m | 120/400 | 150/600 |

| Max. aggregate diameter | mm | Scree: 40 | Scree: 40 | |

| Inside diameter of delivering pipe | mm | Ф125 | Ф125 | |

| Dimensions: length x width x height | mm | 3500x2200x2700 | 5800x2200x2600 | |

| Total weight | kg | 3800 | 6800 | |

| Items | Units | ABJZ30D | ABJZ40D | |

|---|---|---|---|---|

| whole performance of machine | Max. theo. concrete output(L./H) | M3/h | 30 | 40 |

| Max.concrete pumping pressure(H./L.) | MPa | 10 | 10 | |

| Distribution valve type | S Valve | S Valve | ||

| Concrete cylinder diameter x stroke | mm | Ф140X1000 | Ф180X1000 | |

| Hopper capacity | L | 400 | 400 | |

| Outlet diameter | mm | Ф150 | Ф150 | |

| Power system | Electrical engineering power | KW | 37 | 45 |

| Rotate speed | r/min | 1480 | 1480 | |

| Hydraulic system | Circuit type | Open circuit | Open circuit | |

| Pumping system pressure | MPa | 26 | 26 | |

| Mixing system pressure | MPa | 6-8 | 6-8 | |

| Capacity of oil tank | L | 260 | 370 | |

| Other parameters | Max. Theoretical Vertical/Horizontal Conveying Distance | m | 120/300 | 120/500 |

| Max. aggregate diameter | mm | Slick/scree:10/20 | Slick/scree:40/50 | |

| Inside diameter of delivering pipe | mm | Ф100 | Ф125 | |

| Dimensions: length x width x height | mm | 4500x1750x1600 | 4200x2300x3150 | |

| Total weight | kg | 3000 | 4500 | |

Concrete Mixing & Pumping Solutions

Concrete pump can be combined with concrete mixer, concrete mixer truck, self-loading mixer truck, and concrete batching plant to improve work efficiency.

Concrete Mixer Pump & Batching Machine

- It integrates the functions of aggregates batching, concrete mixing and pumping into one, this greatly saves on labor costs and time.

- 2.It occupies less floor space, making it suitable for construction sites with limited space.

Concrete Tralier Pump & Self-loading Concrete Mixer

- The self-loading mixer truck can automatically load materials such as cement and aggregates, mix them, and then transport them over long distances via a trailer pump.

- Both self-loading trucks and trailer pumps have strong mobility and can be flexibly moved according to the needs of the construction site.

Concrete Tralier Pump & Concrete Batching Plant

- This combination can quickly transport the concrete produced by the mixing plant to the construction site.

- This method of continuous delivery greatly improves construction efficiency and maintains the freshness and performance of the concrete.

Global Projects

ABJZ40C Concrete Mixer Pump for Building Construction Project in the Philippines

- Mixing Capacity: 40m³/h

- Pumping Distance: 80m

- Diesel engine model: Weichai

- Application Field: ABJZ40C diesel concrete mixer pump has been shipped to the Philippines and working normally at the construction site, The customer bought the concrete mixer pump equipment for his own factory house construction project. he needs to build several houses to expand the factory.

Get A Quote >

ABJZ40C Concrete Mixer Pump for Building Foundation Work in the Philippines

- Mixing Capacity: 40m³/h

- Pumping Distance: 100m

- Diesel engine model: Weichai

- Application Field: This equipment includes a batching machine and a mixing pump. The batching machine mixes the materials according to a fixed ratio and sends them into the mixing pump for mixing. The concrete produced is of high quality.

Get A Quote >

More Global Construction Projects Application

As a construction equipment manufacturer with more than 40 years of experience, our equipment has been sold to more than 100 countries and regions around the world. We provide concrete production and transportation solutions to many customers around the world to help customers’ construction projects.

ABT30C Concrete Tralier Pump In Indonesia

ABT40C Concrete Tralier Pump In Myanmar

ABT30C Concrete Tralier Pump In Dominica

ABJZ40C Concrete Mixer Pump In Jamaica

ABJZ30C Concrete Mixer Pump In Indonesia

ABJ40C Concrete Mixer Pump In Fiji

ABJZ40C Concrete Mixer Pump In Indonesia

ABT40C Concrete Tralier Pump In The Philippines

ABT40C Concrete Tralier Pump In East Timor

ABJZ40C Concrete Mixer Pump In Nigeria

FAQs

Maximum aggregate size;

Power type, which requires you to determine whether you should choose a diesel engine or an electric motor according to the construction situation;

Pumping distances, including vertical pumping distances and horizontal distances;

Concrete slump. Concrete slump greater than 100 more suitable for pumping.