1.Integrated intelligent control system: one-button start and stop;

2.IOT remote monitoring system: real-time monitoring of equipment operation status;

Applications of the Asphalt Mixing Plant

Asphalt plant is appliable to manufacture paving material that is widely utilized in highway, airport and bridge, freeway, national road, city road, also can be used for road construction on country roads and for repairing road surfaces.

Highway Road Construction

Bridge Road Construction

Industrial Road Construction

Road Construction: Urban and Rural road, Highway Tunnels, etc.

Types of Asphalt Mixing Plants

Asphalt mixing plants are used to produce asphalt mixtures and are widely used in the construction of infrastructure such as roads, bridges, and airports. AIMIX can customize your production capacity, movement methods and working methods according to your needs. The following are the models provided by AIMIX:

ALQ Asphalt Batch Mixing Plant

1. Batch Processing: Ensures precise control over the mix quality;

2. High Production Capacity: Capable of producing a large volume of asphalt efficiently;

3. Advanced Control System: real-time monitoring and adjustments

ensuring optimum performance and mix quality;

Get A Quote

ALT Asphalt Drum Mix Plant

1. Continuous Production: Ensures uninterrupted asphalt production;

2. Energy Efficiency: Optimized for fuel consumption, reducing operational costs;

3. ALT: Ideal for medium, small, non-moving projects.

Get A Quote

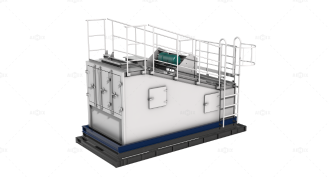

ALYT Mobile Asphalt Drum Mix Plant

1. High cost performance;

2. Suitable for various road construction projects;

3. Dust collector: bag type/water type;

4. ALYT: suitable for small projects that require mobility.

Get A Quote

Asphalt Mixing Plant Cases

Asphalt mixing plants have become increasingly popular worldwide due to their efficiency, reliability, and versatility. These plants have been exported to various countries, for example: the Philippines, Malaysia, Indonesia, Australia, Saudi Arabia, Paraguay, Peru, Chile, Tanzania, Democratic Republic of the Congo, Fiji, Papua New Guinea, Guyana, Jamaica, etc;

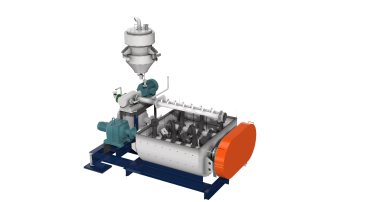

Main Components of the Asphalt Mixing Plant

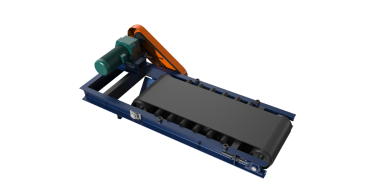

Cold Aggregate Bin: stores and transports cold aggregate

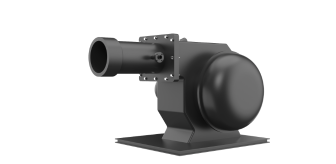

Burner: Provides the heat needed to dry the drum

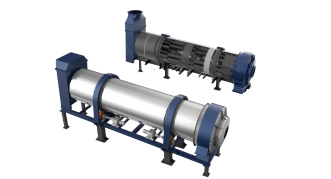

Drying Drum: heats and dries the aggregate

Vibrating Screen: Sifting dry aggregate

Hot Aggregate Bin:stores hot aggregate and maintains temperature

Dust Filter: eliminates the dust generated during the production process

Mixing System: Mix hot aggregate, mineral powder, and asphalt

Control System + IOT System. automated control and monitoring.

AIMIX Service

Consulting and Design

Provide pre-sales consulting services and general planning.

Professional service team provides the analysis, confirmation and improvement.

Provide a model for analyzing the return on investment

Fulfillment Delivery

Information services: synchronization and sharing;

Quality Control (No-Load Test, Inspection Report)

Transportation services (packaging design, reinforcement and protection)

Customer Success

After-sales training

Equipment installation (online orientation, offline service)

Return visit service (understanding the operational status of the equipment)

Related Products

Concrete Batching Plant→

Stabilized Soil Mixing Plant→

Asphalt Paver Machine→