1.Integrated intelligent control system: one-button start and stop;

2.IOT remote monitoring system: real-time monitoring of equipment operation status;

Different Types of Asphalt Mixing Plants

Asphalt mixing plants are designed to produce asphalt mixtures for road construction, maintenance, and repair. They play a vital role in building highways, repairing urban roads, and constructing large-scale bridges. With production capacities ranging from 40 to 400 t/h, we offer a variety of asphalt mixing plants to meet diverse needs. Our main products include the ALQ stationary batch asphalt mixing plant, ALYQ mobile batch asphalt mixing plant, ALT stationary drum asphalt mixing plant and ALYT mobile drum asphalt mixing plant, each tailored for specific hot mix asphalt applications.

Stationary Batch Type

Stationary Batch Type Mobile Batch Type

Mobile Batch Type Stationary Drum Type

Stationary Drum Type Mobile Drum Type

Mobile Drum Type

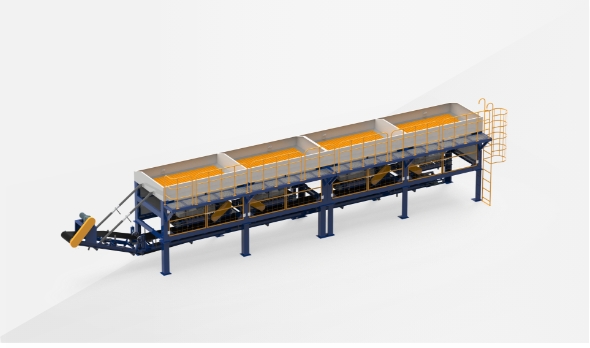

ALQ Stationary Batch Asphalt Mixing Plant

Hot Models: 80t/h120t/h160t/h200t/h

Productivity: 80t/h-400 t/h

Mixer: Twin shaft mixer,

Dust filter: Bag dust filter/ Water dust filter

Application Fields: Widely used in highway construction, airport runways, large infrastructure projects

Get A Quote >

ALYQ Mobile Batch Asphalt Mixing Plant

Hot Models: 80t/h100t/h120t/h

Productivity: 80t/h-140 t/h

Application Fields:

1. No disassembly or assembly required for transfer, and the equipment can be put into production in 2 days;

2. Calibration system to ensure production accuracy;

3. Equipment container size design to adapt to overseas container transportation;

Get A Quote >

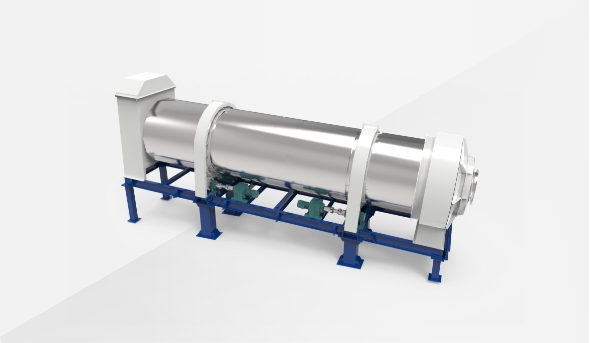

ALT Stationary Drum Asphalt Mixing Plant

Hot Models: 40t/h60t/h80t/h120t/h

Productivity: 40t/h-120 t/h

Mixer: heat and mix raw materials using drying systems and drum mixers

Dust filter: Bag dust filter/ Water dust filter

Application Fields: Ideal for large-scale asphalt production in highway, airport, and infrastructure construction.

Get A Quote >

ALYT Mobile Drum Asphalt Mixing Plant

Hot Models: 40t/h60t/h80t/h120t/h

Productivity: 40t/h-120 t/h

Mixer: heat and mix raw materials using drying systems and drum mixers

Dust filter: Bag dust filter/ Water dust filter

Application Fields: Compact and with a mobile chassis for easy transportation and quick relocation. Widely used in highway construction, airport runways, large infrastructure projects

Get A Quote >

Aimix Cases Of Asphalt Mixing Plants in Different Countries

Asphalt mixing plants have become increasingly popular worldwide due to their efficiency, reliability, and versatility. These plants have been exported to various countries, for example: the Philippines, Malaysia, Indonesia, Australia, Saudi Arabia, Paraguay, Peru, Chile, Tanzania, Democratic Republic of the Congo, Fiji, Papua New Guinea, Guyana, Jamaica, etc;

Model ALYT80

Productivity: 80 t/h

Location:Papua New Guinea

Our Advantages

Our clients can earn back your investment cost in one year. The actual production capacity is higher than theoretical capacity, the production efficiency is higher, and it can be installed quickly, shortening the production cycle. The after-sales service response speed is very fast, which can be very satisfying.

Model ALQ100

Productivity: 100 t/h

Location: Indonesia

Project Details

Previously, the company relied on buying asphalt mix for their projects. However, by investing in the ALQ100 asphalt mixing plant, they are now able to control raw material costs and ensure the consistent quality of asphalt production, which has greatly enhanced their overall efficiency.

The customer has also placed an order for two additional 100-ton stone crushing plants, which are currently in production. These crushing plants are specifically designed to supply materials for the asphalt mixing plant.

Model ALT40

Productivity: 40 t/h

Location: Fiji

Project Details

A customer in Fiji recently purchased the ALT40 Asphalt Mixing Plant for a major road construction project. After successfully using the plant for their first project, the customer decided to expand their operations by purchasing additional equipment, including a AJG35 dry type concrete batching plant.

Model ALT120

Productivity: 120 t/h

Location: Guatemala

Project Details

The customer also emphasized the plant’s simple design and low operational costs as key advantages. These features enabled them to optimize their budget, main factors influencing Latin American customers to order this product.

Model ALYT120

Productivity: 120 t/h

Location: Ecuador

Project Details

The ALYT120 asphalt drum mix plant’s flexibility was particularly praised. The customer highlighted that its easy transportation and quick setup allowed for seamless movement between multiple construction sites, significantly reducing downtime. This feature was crucial in regions with limited infrastructure and challenging logistics, enabling them to complete projects on schedule and within budget.

Model ALQ120

Productivity: 120 t/h

Location: Malaysia

Project Details

Malaysia’s diverse market and stringent infrastructure requirements call for reliable solutions, and AIMIX exceeded expectations by providing not only high-quality equipment but also comprehensive pre- and post-sales support. The customer commended the prompt responses to queries, technical assistance, and regular follow-ups, which ensured the plant operated at peak efficiency throughout the project.

Model ALQ80

Productivity: 80 t/h

Location: Indeonsia

Project Details

With AIMIX’s excellent after-sales support, including timely maintenance and spare parts availability, the customer was confident in meeting both current and future market demands. They strongly recommended the ALQ160 Asphalt Mixing Plant as a reliable and efficient solution for Indonesia’s infrastructure development needs.

Model ALQ160

Productivity: 160 t/h

Location: Kazakhstan

Project Details

The customer expressed high satisfaction with the ALQ160 asphalt mixing plant, emphasizing its significant impact on a large-scale road construction project in Kazakhstan. They highlighted the plant’s impressive production capacity of 160 tons per hour, which allowed them to meet tight deadlines while maintaining excellent asphalt quality.

Model ALQ80

Productivity: 80 t/h

Location: Kazakhstan

Project Details

The robust design has proven durable even in challenging weather conditions. AIMIX’s local service team was instrumental in the smooth installation process, providing prompt assistance and technical support.

Model ALQ80

Productivity: 80 t/h

Location: Philippines

Project Details

They are highly satisfied with its performance and reliability. From delivery to setup, the process was seamless, thanks to AIMIX’s dedicated support team. It is perfectly suited for the diverse road construction projects.

Applications of the Asphalt Mixing Plant

Asphalt plant is appliable to manufacture paving material that is widely utilized in highway, airport and bridge, freeway, national road, city road, also can be used for road construction on country roads and for repairing road surfaces.

Highway Road Construction

Bridge Road Construction

Industrial Road Construction

Road Construction: Urban and Rural road, Highway Tunnels, etc.

Production Videos of an Asphalt Mixing Plants:

These asphalt plants provide the consistency that is crucial to your mix quality. All plant processes and components are carefully developed to ensure that feeding, heating, drying, screening and mixing seamlessly blend together.

Main Systems Of Asphalt Mixing Plant

The asphalt mixing plant is mainly composed of cold aggregate supply system, drum dryer, Coal Burner, mixing tower assembly, vibrating screen, filler supply system, weighing and mixing system, asphalt storage, bitumen supply system, etc

AIMIX Service

Original parts supply

Original parts supply